The Adaplast® lining is an external lining to protect the concrete directly on-site ensuring business continuity. The Adaplast ® lining provides high protection and elasticity of the treated surface. It can be used to protect bunds as well as any concrete floors.

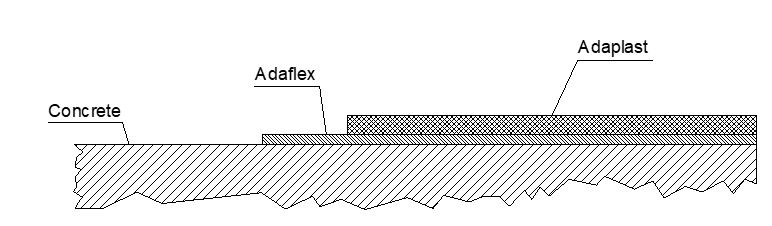

Structure of the lining system:

Preliminary Works:

- Surface treatment, cleaning, degassing, remove all oil residuals

Coating Application Technology:

- Application of Adaflex® primer with a roller

- Application of the cover layer Adaplast® by spreader or roller

Installation note:

The above information is based on tests by approved institutes (e.g. TÜV Süd Germany) and many years of experience. As the lining performance depends on correct installation, we offer application courses for certified installers and installation supervisors and provide certificates which shall be renewed every 3 years.