Wolftank Austria team has recently applied its tank lining system DOPA® 6N in China.

The prevention of environmental contamination caused by hazardous storage liquids in underground storage tank is an important topic addressed by the Government of People’s Republic of China.

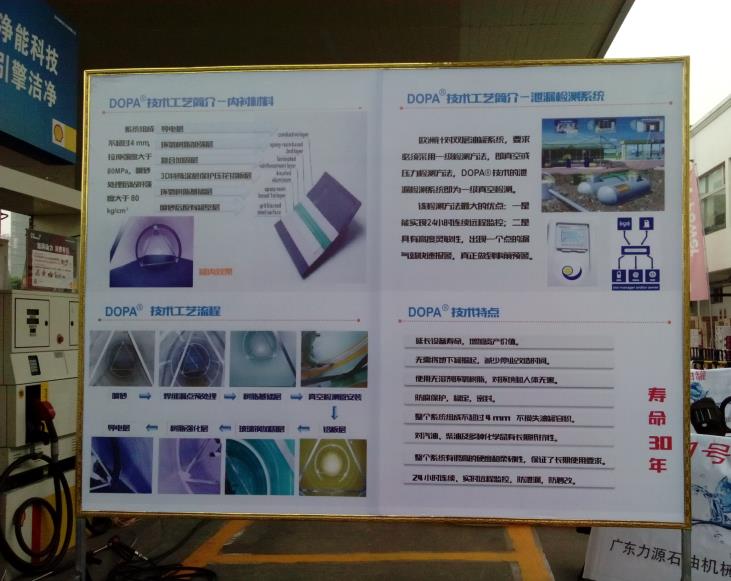

Suitable for this issue, Wolftank Austria provides the DOPA® 6N technology. This solution monitors 24/7 the tanks integrity and protects the soil from contamination with potentially toxic liquids in underground and above ground fuel storage facilities.

The context

Nowadays, due to its increasing relevance, many countries are taking measures to control and prevent leakage of hazardous liquids into the ground. Most of them are issuing laws requiring the installation of double-walled underground storage tanks with corresponding leak detection units.

In the Chinese case, the normative GB/T300.40.1-7 has been published and it is very similar to the one the European Union did in the normative EN13160-1 to EN13160-7.

The scope of the project

Shell is an important leading player in the retail market in China. During the last times, especially the retail service stations in Chengdu, in the Sichuan province, are showing a trend of raising density.

Then, Shell identified the interest to promote a tank lining campaign for double wall transformation in China. The focus was to implement worldwide the quality and the safety standards.

Wolftank Austria standards experienced for more than 20000 tank linings all around the world were totally aligned with the standards requested by Shell. Therefore, our team introduced them to our local partner Guandong Liyuan Oil Construction Company.

The challenge

Our team needed to train the contractor Liyuan on tank lining and in confined spaces works. In addition, they needed to support Liyuan in the implementation of the tank lining campaign.

Firstly, Wolftank Austria and Liyuan compiled in close discussion with Shell China a documentation package describing:

- the coating technology for training

- quality documents and quality control

- HSE booklet with further risk assessment documents for each step of the tank lining

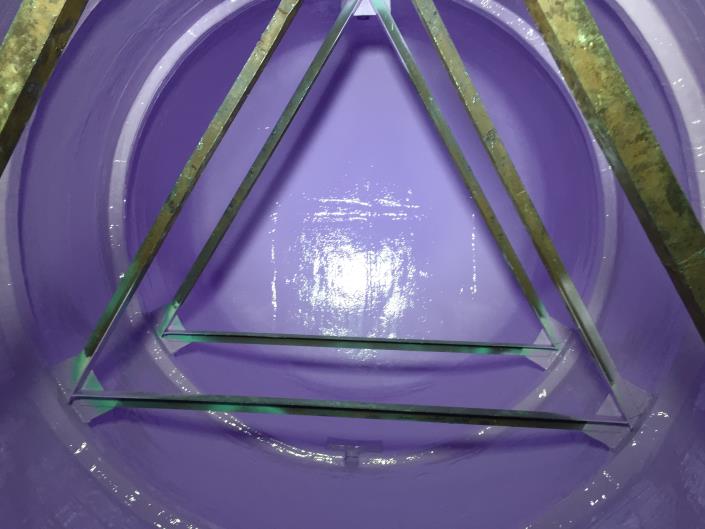

During the training that our team organized, Wolftank compiled the “Epoflex® 590 & DOPA® 6n Training” information in order to explain the coating technology, the installation quality and the quality control, as well as the HSE measures for safe lining installation.

The solution

At that moment, Liyuan already have the ability to act at Shell’s construction site. Thus, the team started a pilot of a double-tank liner reconstruction. And they selected for it the Jinfu Lu gas station, located in Chengdu -Sichuan province-. As a next step, a delegation of 50 people of Shell Global and Shell China visited the site in order to revise the safety measures.

During the execution phase, Liyuan got a further training on the works, both theoretically and practically. In addition, they had Wolftank Austria engineers’ support during the whole process.

Regarding Risk Prevention, while the project implementation phase, the team made a safety observation about the safe drilling of holes for the double wall measurement and aspiration pipes. They explained this to the partner, as well as the risk with the underscoring of proper safety measurements such as continuous LEL monitoring and ventilation during this step. But once the project finished, there was also a continuous analysis of the implemented HSE standards.

The outcome

After the lining project, a total of 4 underground storage tanks were lined. The duration of the project was 22 days. That means that the interruption of the service could be cut by more than 50% compared to the average duration of a tank replacement project.

In conclusion, Shell China agreed on the possibility to implement European standards in tank lining in their country. With our partner Liyuan, it is completely possible.

Discover more about our Chinese team located in Shanghai, by clicking here (EN) and here (CN).