DOPA® 6 Lite is being successfully applied in Germany through DRK32. The firm, as subsidiary company of the Wolftank Group, operates in Germany. Specifically in the field of tank terminals and retail stations.

This country has the second most gas stations in whole Europe. Furthermore, the German gas station industry has a very high environmental protection awareness and focus also on soil and groundwater protection. If not protected well, the large number of gas stations lead to increased risk of possible damages or environmental pollution. However, tanks continue to age and sooner or later a rehabilitation is necessary.

The scope of the project

As the business worked very well in the diesel tank sector, we wanted to find a competitive solution for petrol tanks as well. Thus, DRK32 came to the consideration to adapt the system DOPA® for the requirements of the German customers and to use for petrol tanks.

The challenge

We have a very good network in Germany to the operators of gas stations, corporations and industry. But we had to convince all of them that our new product is an equivalent solution as the traditional way to install the DOPA® system for the petrol tanks.

With this purpose, DRK32 started to participate in many events and fairs and explained the benefits of our system.

The solution

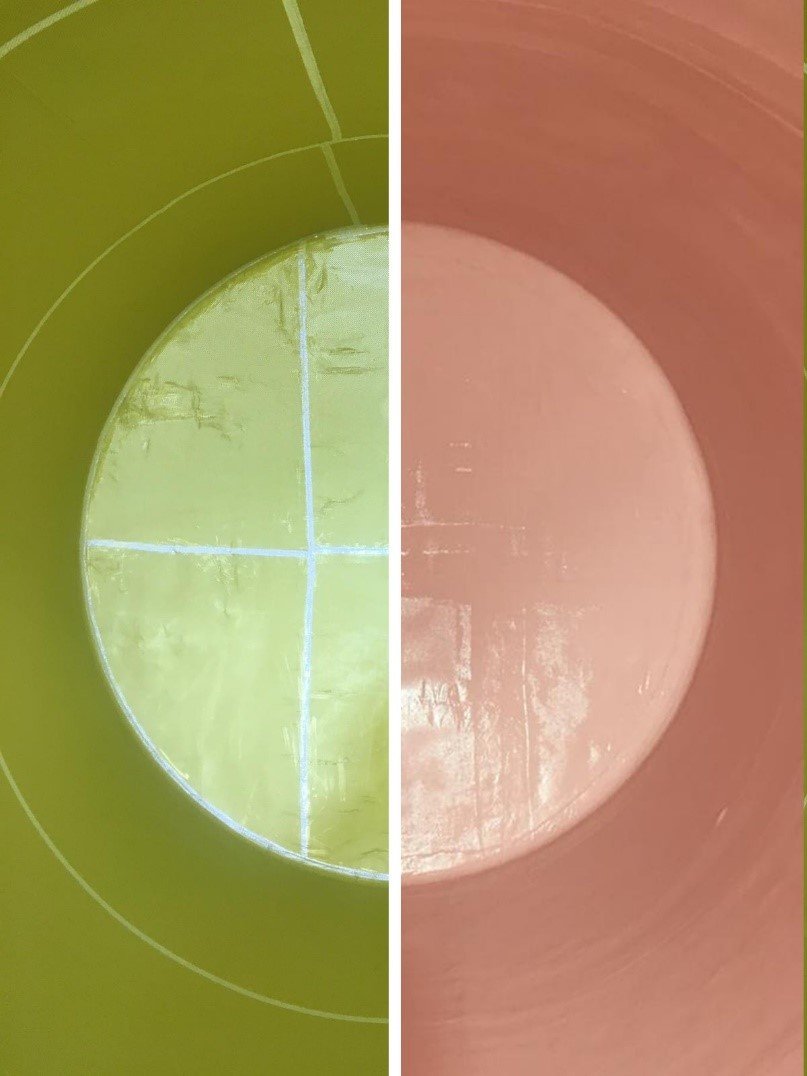

The functionality of the system is identical to the traditional way of installing. Since the integrity of the first wall (tank shell) of a double wall system is assured, the second wall is made with the DOPA® system. The material usage of the system is less than DOPA®. Therefore, the installation time can be approximately the 50%.

DRK32 invested in new equipment, tools and small wares especially designed to have a fast and flexible installation of the DOPA® 6 Lite system.

The outcome

Our team managed the field pilots and first installations for DOPA® 6 Lite and now they are able to fulfil the demands of the German market. After completing the pilot project, they received several follow-up orders.

Definitely, DOPA® 6 Lite‘s high resistance to aggressive fuels such as E10 brings a big advantage for customers. In addition, the short downtime makes the system highly competitive for the double-wall lining of tanks.

Now, the expected extension of the tank lifetime is up to 20 years. That means the highest of the solutions available on the market.

In conclusion, after this innovative development, if a customer needs a lining system not only for diesel tank but for petrol tank, we can easily offer a really competitive solution.